Kladana lets you create a professional schedule of the cost of goods manufactured without the hassle of manual data entry. All your production cost details are compiled into clear, structured reports. With COGM, you can clearly see the total investment required to turn raw inputs into finished products. Yes, the cost of goods sold gym bookkeeping typically includes the cost of goods manufactured. Making sense of COGM and having efficient systems to measure and track them is critical to your survival as a manufacturing business.

Related AccountingTools Courses

This deduction from total manufacturing costs is critical as it ensures that financial statements reflect costs pertaining solely to finished goods, thereby directly influencing COGM assessments. Understanding how to calculate the cost of goods manufactured correctly is essential in accounting and finance as it helps businesses determine their gross profit margin for each product produced. It includes calculating all manufacturing-related expenses such as raw materials, labor wages, factory overhead expenses, depreciation on machinery or equipment used in production, etc. The Cost of Goods Manufactured (COGM) is the total cost incurred by a company to produce goods during a specific period. It represents the sum of direct materials, direct labor, and manufacturing overhead costs for items that move from the production line into finished inventory.

- COGM also allows management to identify cash drains, adjust prices, and track the development of the business.

- Please review the formula below that determines a company’s end-of-period work in progress (WIP) balance once we go on to the COGM formula.

- In contrast to merchants, manufacturers have special inventory categories including work-in-process (WIP), raw materials, and finished goods.

- These items represent an intermediate stage in the production pipeline, holding value from the direct materials, direct labor, and manufacturing overhead costs already invested.

- This leads to a more efficient production process and lowers the total manufacturing cost.

- Direct materials refer to all the raw materials used to produce the finished product or in its final form.

- The cost of goods manufactured formula is often confused with the cost of goods sold formula, but these two formulas differ.

Why Calculating COGM is Important for Production?

If you don’t adjust QuickBooks your total manufacturing costs for changes in WIP inventory, your COGM calculation will be inaccurate. COGM is the total cost of producing goods during a specific period, including direct materials, direct labor, and manufacturing overheads. Indirect materials are supplies used in the production process, but that cannot be directly linked to a particular good or production unit.

Unifying All Production Costs in One System

- The calculation of the Cost of Goods Manufactured (COGM) combines manufacturing costs incurred during a period with changes in work-in-process inventory.

- Incorporating technology and automation in talent development can enhance productivity and reduce overhead costs.

- Calculate COGM by adding the costs of direct materials, direct labor, and manufacturing overhead incurred during production.

- The beginning WIP is what’s left unfinished from the previous period, while the ending WIP is what’s still in progress after finished goods are accounted for.

- The concept of lean manufacturing is all about reducing waste to an absolute minimum.

On the other hand, if the selling price is too high, consumers might look for similar products at lower prices. Knowing your COGM accurately is essential because this number helps a business determine the product’s selling price. If the selling price is set too low compared to the COGM, the business could incur losses. Establishing robust relationships with suppliers plays a key role in preventing supply chain issues and maintaining a steady flow in the production process. COGM refers to the cost of goods that have been manufactured during a specific period, while COGS refers to the cost of goods that have been sold.

Turning Data into Valuable Insights

In contrast to merchants, manufacturers have special inventory categories including work-in-process (WIP), raw materials, and finished goods. To calculate cost of goods manufactured, you first need to determine all your production costs and WIP inventory. In summary, COGM reflects the total cost of manufacturing goods – whether they were sold or not – while COGS represents the cost of only those goods that were sold to customers during a specific period.

The cost of goods manufactured (COGM) refers to all the costs involved in producing a product, including direct labor, indirect labor, raw materials, and overhead costs. Total manufacturing cost (TMC), also called total cost of production, is the all-in number for what it takes to make goods during a specific period. It covers everything tied to production–raw materials, labor, and factory overhead. Unlike general expenses such as utilities or marketing, COGM sticks strictly to manufacturing costs.

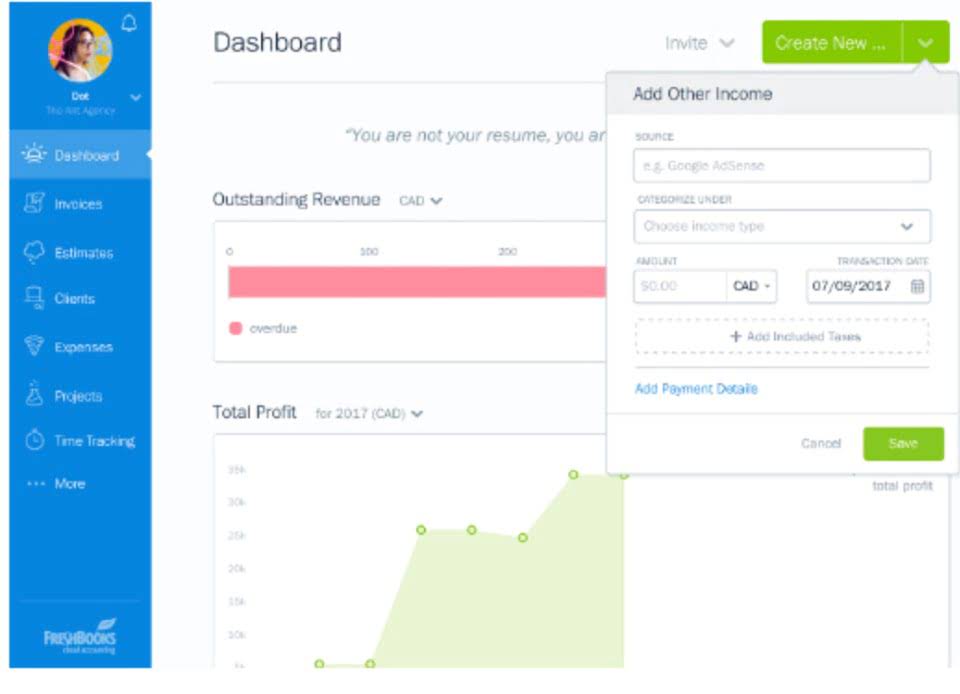

Save time and money by automating your processes

Indirect materials are often included in the factory overhead costs in the cost of goods manufactured (COGM) calculation. Every product tells a story–not just of design and delivery but of the costs and decisions that bring it to life. For compute cost of goods manufactured businesses, understanding the cost of goods manufactured (COGM) isn’t just about crunching numbers; it’s about uncovering the real drivers behind profitability and efficiency. From tracking production expenses to setting competitive prices, COGM holds the key to staying in control of your operations.

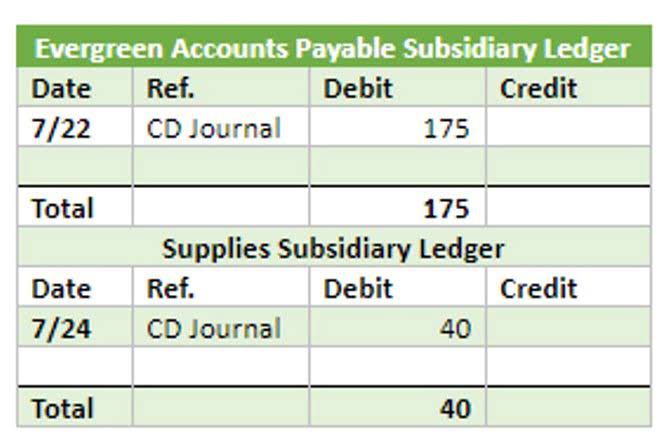

The same applies to WIP inventory, which represents the value of partially completed goods. The journal entry credits WIP inventory to reflect the portion of manufacturing costs that have been added to the work in process. To calculate the cost of goods manufactured (COGM), first add up all the costs incurred during the manufacturing process within a specific period.